Laser cutting has revolutionized manufacturing across various industries. With its precision and versatility, the technology allows companies to shape raw materials into various parts and products.

With laser cutting, it’s possible to cut materials like metal, plastic, wood, and glass with remarkable accuracy. Because of this, it plays a pivotal role in everything from aerospace engineering to textile industry and medical field. Each industry uses its strengths in unique ways to create vital components and products.

In this article, we will explore the multifaceted applications of laser cutting technology in 10 major industries.

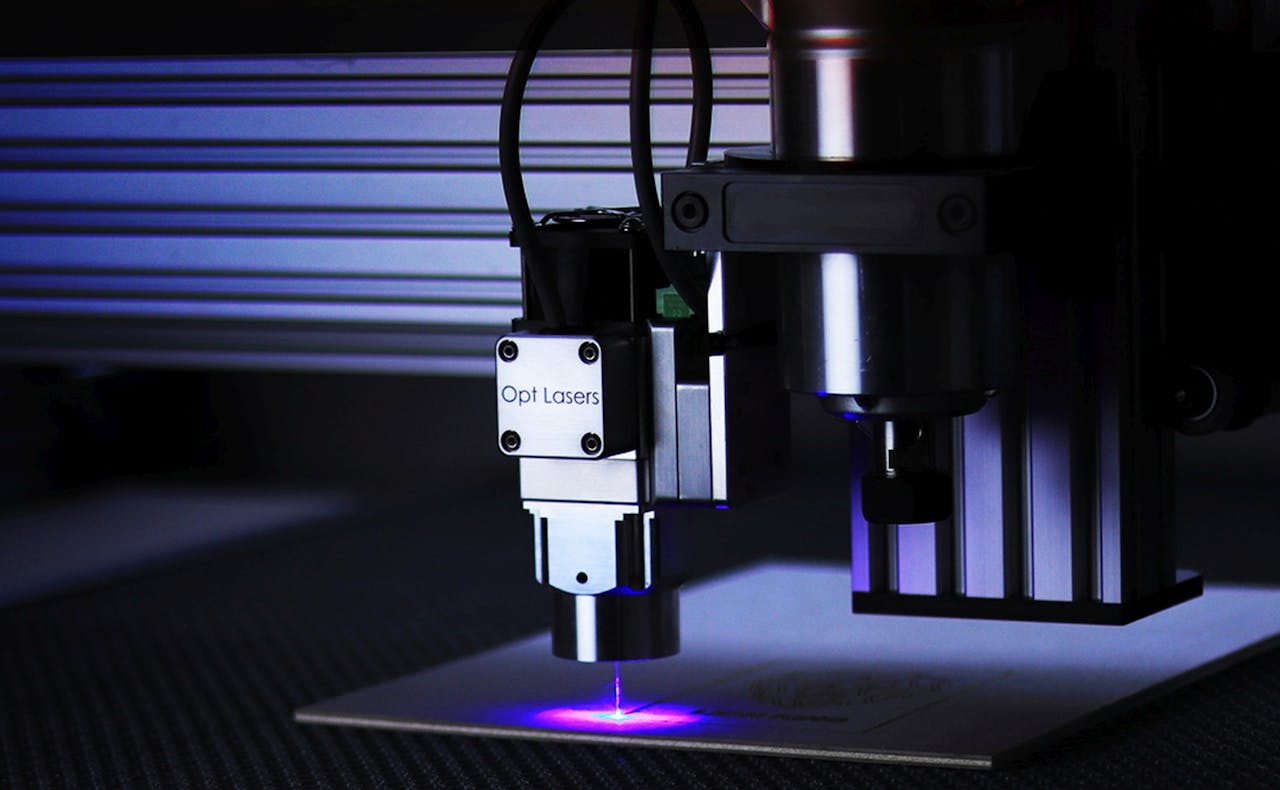

What is Laser Cutting?

Laser cutting is a precise method for cutting a variety of materials using a high-powered laser. In this process, a laser source directs a laser beam to the materials to be cut.

The beam cuts something by focusing intense heat onto very small points, either melting, burning, or vaporizing away the material. It allows for very clean and precise cuts, with a high level of control over the cutting path and speed.

There are a few main ways that laser cutting works:

- CO2 laser cutting uses carbon dioxide gas to generate the beam. These can cut thicker materials, like stainless steel and aluminum.

- Fiber laser cutting delivers the beam through an optic fiber. They can cut a range of materials but tend to be more expensive.

- Solid state lasers use a crystal to generate the beam and are commonly used on plastics and aluminum alloys.

Laser cutting machines are computerized numerical control or CNC machines, meaning the laser follows pre-programmed patterns. For this reason, they can cut complex shapes and detailed patterns with a high degree of accuracy.

Laser cutters are found in many industries like manufacturing, shipbuilding, automotive, textile, and more. Their precision makes them suitable for projects requiring intricate cuts and elaborate designs.

Applications of Laser Cutting in 10 Industries

Numerous industries use laser cutting technology for its precise, versatile machine operations. We will focus on 10 sectors that utilize this method for producing high-quality parts and products.

1. Automobile Industry

The industry relies on complex and delicate laser cut parts, made of materials like stainless steel and aluminum alloys.

Some key applications of laser cutting in automobiles include precision cutting of body panels. It helps enhance a vehicle’s aesthetics and aerodynamics. This method’s extreme accuracy is useful in shaping engine components. Manufacturers also use it for punching and trimming automotive templates, especially during new model development and low-batch production.

Cutting with a laser offers more efficiency than traditional fabrication processes. For example, a fiber laser cutter’s high power and accuracy is essential in automaking where millimeters make a difference. And a 3D laser cutter can save plenty of mold models that helps with faster production.

2. Ship Manufacturing

Laser cutting ensures the structural integrity of a ship’s framing systems, with exact dimensions for ribs, frames, and bulkheads. Also, its ability to cut thick steel plates precisely is invaluable for forming the hull of a vessel.

Additionally, precision laser cutting provides the accuracy needed to assemble the numerous steel decks and sheets that make up a ship’s flooring. The technology is also great for cutting sophisticated parts for a vessel’s superstructure, including the bridge and living quarters.

Laser technology can help achieve the tight tolerances required for frames around doors, hatches, and portholes to maintain watertight integrity.

Some important ship parts that can be made using laser cutting are:

- Hull plates and sections

- Structural ribs, frames, and bulkheads

- Decking plates and components

- Superstructure elements like bridge structures

- Door, window, and hatch frames

- Engine components

- Pipework and flanges

3. Aerospace Field

In the aerospace industry, laser cutting technology is crucial for producing lightweight, high-strength components with extreme precision. Some key laser cutting applications include:

- Cutting and engraving of metals and alloys, such as aluminum alloy, used in aircraft construction.

- Producing sophisticated internal structures that require meticulous accuracy, such as parts with holes.

- Meeting strict tolerance levels for aerospace components. The precision of laser cutting maintains the structural integrity of materials, which is paramount for safety.

- Reducing weight through more efficient cutting of 3D designs compared to older methods. Less weight means improved fuel efficiency and flight performance.

- Speeding up production by automating formerly manual cutting tasks.

In short, laser cutting enables the aerospace industry to manufacture lighter, stronger, and more precise parts for modern aircraft and space vehicles.

4. Nuclear Industry

One of the main applications of laser cutting in this sector is dismantling and demolishing nuclear power plants that have reached the end of their life cycles.

Thick steel reactor components require precision cutting, which lasers can provide faster and more accurately than other methods. It reduces the cost of taking these plants apart.

Within active nuclear plants, lasers are utilized for maintenance and repairs. Rather than removing large sections of worn components, a laser can precisely cut out specific parts, like bellow lips, coolant channels, or pressure tubes. It’s also well-suited for remote cutting of radioactive materials underwater or in hazardous environments.

5. Machinery Manufacturing

Laser cutting is widely used in machinery manufacturing. It can cut steel, aluminum, and titanium with accuracy for machine parts and components. It’s an effective method for cutting heavy gauge steel or fine‐tuning lightweight metals. With this technology, you can manufacture everything from large industrial machines to small parts for technical applications.

The ability to adapt to different material thicknesses without losing precision is a core benefit of this method. Machinery makers use it for its consistency in cutting various metals for diverse needs.

6. Steel Industry

Laser cutting has many uses in the steel fabrication industry. It can cut intricate shapes and patterns out of steel sheets with amazing precision. This makes it ideal for producing steel frameworks and architectural elements.

The technique is also suitable for larger scale structural steel projects for things like bridges, tunnels, and building frameworks.

Some specific applications include cutting connection plates and base plates for construction. Lasers slice through different types of steel, like stainless steel and mild steel, leaving an extremely small kerf width, which minimizes material waste.

Using laser over manual methods in this industry ensures worker safety. It’s also better than alternatives like plasma cutting for achieving tighter tolerances.

7. Textile Industry

One primary use of laser cutting in this industry is cutting complicated fabric patterns for garment production. This method gives designers far more freedom to experiment with complex designs. They can cut elaborate shapes in a wide range of materials, from lightweight cotton to tough leather.

Beyond pattern cutting, laser technology is useful for perforating fabrics. Sportswear and outdoor apparel brands commonly use perforated materials to increase breathability.

Backpack manufacturers laser cut ventilation holes into lightweight materials. The armor industry also employs perforation, such as with bulletproof vests. Leather goods makers take advantage of laser etching for logos and other precise engraved markings.

8. Petroleum Industry

The petroleum industry uses laser cutting technique for:

- Drilling underground

- Cutting heavy metals

- Cladding materials with a protective coating

- Engraving machinery

With this technique, manufacturers create heavy-duty slotted liners that separate oil from sediments in wells. These liners were traditionally made through diffusion-cooled CO2 slab lasers but modern kilowatt fiber lasers now allow for faster and more precise cutting. Lasers can perform both piercing and continuous cutting in one step for closed features like slots, maintaining a consistent cut width.

Beyond liners, lasers are used for cutting metals throughout oil rig machinery. Other laser applications include drilling through rock more quickly than mechanical methods, debris removal in wells, providing corrosion resistant cladding on equipment, and permanent marking for identification.

9. Communication Storage

In communication storage technologies, laser cutting’s role is rather indirect. It’s not used in making hard drives, servers, or cloud storage. However, you can see its use in prototyping new storage solutions.

The method allows engineers to create precise, customized enclosures and components with great speed and flexibility. This enables rapid iteration as designs evolve. Quick modification of parts in response to testing helps accelerate the engineering process.

Laser cutting also helps meet the demanding requirements for specialized storage equipment. Networking devices and server racks benefit from laser-cut custom enclosures made of durable materials, like acrylic and sheet metal.

10. Medical Cosmetology

Laser cutting has opened up new possibilities in medical cosmetology procedures. It allows for highly precise incisions with minimal impact on surrounding tissues. Such precision is vital when the goal is to minimize scarring.

Lasers are great for creating tiny incisions needed for eyelid or liposuction surgeries. The laser beam itself helps to seal blood vessels as it cuts, resulting in less bleeding during operations and quicker healing afterward.

Some other applications of laser in medical cosmetology are:

- Laser skin resurfacing removes a thin outer layer to promote new, smoother cell growth.

- Laser-assisted lipolysis melts away fat cells in targeted areas like the abdomen or thighs.

- Reshaping and improving existing scars through a process called scar revision.

Pros and Cons of Laser Cutting

Laser cutting is used in various industries because of the numerous benefits it offers. However, it also presents some drawbacks. So, let’s explore the pros and cons of this emerging technology.

Laser Cutting Advantages

- Precision Processing: It allows for pinpoint cuts thanks to the narrow energy beam and precise positioning controls. Even for delicate materials, it’s possible to cut complex designs quickly.

- High Speed Cutting: It is incredibly fast, often 10 times quicker than bandsaws and 50-100 times faster than wire cutting for sheet materials.

- No Contamination: Unlike traditional cutting methods, laser cutting uses only an energy beam or some gasses, avoiding risks of chemical contamination on the finished products.

- Minimal Heat Affected Zone (HAZ): Laser cutting involves an extremely localized heat source, creating a very narrow heat affected zone (HAZ) around the cut edge. It minimizes distortion and reduces the need for post-processing.

- Versatility in Materials: Lasers can cut a wide range of materials from plastics to metals, like titanium, steel, tungsten, etc.

Laser Cutting Disadvantages

- Thickness Limitations: Most laser cutters can only cut a material up to around 12mm thick, and thicker cuts are very slow.

- Harmful Emissions: Certain materials like PTFE release toxic gasses, like phosgene, when cut with lasers.

- High Energy Use: While faster, laser cutters for metal and other things consume more power during operation than other CNC tools.

- Upfront Equipment Costs: Suitable laser cutting machines range from $2,000 for lightweight use up to $150,000 for industrial systems. This is higher than comparable CNC equipment, which can start at $8,000.

Conclusion

Laser cutting has transformed manufacturing across countless industries. This versatile technology allows for precise shaping of various materials, from delicate fabrics to thick steel. From crafting car parts to drilling underground, it plays a vital role in the modern industrial sector. Its accuracy, speed, and clean cuts make it a valuable tool for a wide range of applications.

Ready to revolutionize your production with laser cutting technology? Contact Zintilon for top-tier CNC metal fabrication and laser cutting services to see the difference precision makes. Let our engineering experts optimize your design for production.